Coca-Cola, one of the world’s most iconic and recognizable brands, has a rich history dating back to its inception in 1886. Established by John Stith Pemberton, the brand has evolved into a global beverage giant, offering a diverse range of products, including the flagship Coca-Cola beverage, as well as an array of juices, teas, and energy drinks.

Recognizing the need for a comprehensive and integrated solution, the company embraced the implementation of SAP ERP as a transformative initiative. This endeavor aimed to unify and streamline various business processes, ranging from order management to production and financials, fostering a more responsive and interconnected organizational structure.

In this case study, we will understand more about Coca-Cola’s preference for SAP ERP, its benefits and the inside story.

Background of Coca-Cola’s Business Operations

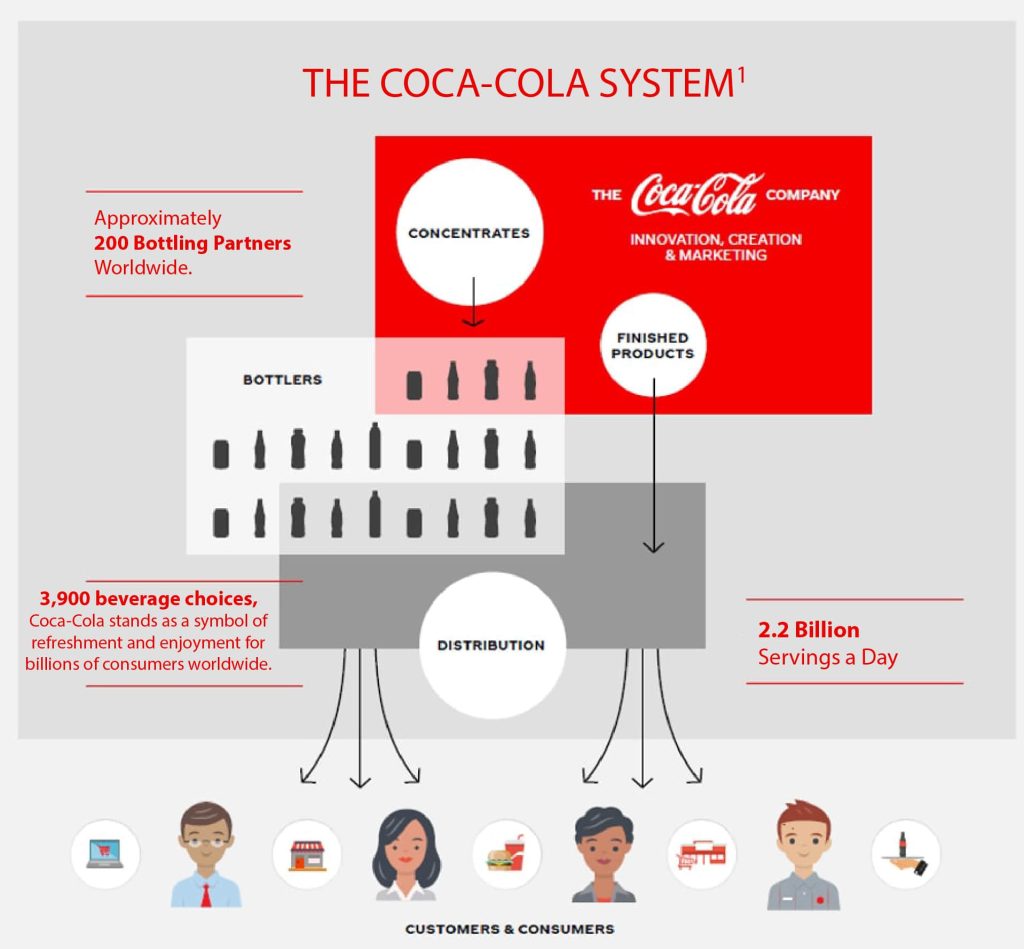

With a presence in over 200 countries and a portfolio boasting over 3,900 beverage choices, Coca-Cola stands as a symbol of refreshment and enjoyment for billions of consumers worldwide.

Coca-Cola’s commitment to brand consistency, marketing prowess, and strategic partnerships has solidified its position as a symbol of refreshment and a testament to the enduring power of iconic brands.

Challenges Faced in Order Management, Production, and Financial Processes

Order Management

- Complex Supply Chain: The global scale of Coca-Cola’s operations led to a complex and intricate supply chain, resulting in challenges related to order processing, tracking, and fulfillment.

- Manual Processes: Manual entry and management of orders proved time-consuming and prone to errors, impacting the efficiency of the order fulfillment process.

Production

- Diverse Product Portfolio: With a vast and diverse product portfolio, Coca-Cola faced difficulties in managing production schedules, inventory levels, and demand forecasting accurately.

- Bottlenecks and Inefficiencies: Existing production processes were susceptible to bottlenecks and inefficiencies, hindering the company’s ability to respond swiftly to changing market demands.

Financial Processes

- Legacy Systems: Coca-Cola’s financial processes relied on legacy systems, leading to fragmented data, delayed reporting, and a lack of real-time insights into financial performance.

- Manual Financial Transactions: Manual handling of financial transactions, including invoicing and expense tracking, increased the risk of errors and hampered the speed of financial decision-making.

Objectives of Implementating SAP ERP

The implementation of SAP ERP at Coca-Cola was driven by the need for a reliable, integrated, and scalable solution that could address specific challenges and strategically align with the company’s objectives in streamlining order management, enhancing production efficiency, and improving financial processes.

The implementation of SAP ERP at Coca-Cola was driven by specific strategic objectives aimed at addressing key challenges and optimizing core business functions:

Streamlining Order Management

- Automation and Efficiency: One of the primary objectives was to automate and streamline the order management process. SAP ERP introduced automation features that reduced manual intervention, minimized errors, and accelerated the entire order lifecycle, from entry to fulfillment.

- Real-Time Visibility: SAP provided real-time visibility into the order pipeline, enabling Coca-Cola to track orders, monitor inventory levels, and respond promptly to customer demands. This enhanced transparency and responsiveness in order management.

Enhancing Production Efficiency

- Optimized Production Planning: SAP ERP played a pivotal role in optimizing production planning and scheduling. By leveraging real-time data on inventory levels, demand forecasts, and production capacities, Coca-Cola could minimize bottlenecks, optimize resource utilization, and enhance overall production efficiency.

- Inventory Management: SAP’s capabilities improved inventory management, ensuring that Coca-Cola maintained optimal stock levels, reduced waste, and improved the overall agility of its production processes.

Improving Financial Processes

- Automation of Financial Transactions: SAP ERP automated financial transactions, including invoicing and expense tracking. This automation not only streamlined financial workflows but also reduced the likelihood of errors, improving the accuracy and efficiency of financial processes.

- Real-Time Financial Insights: SAP provided real-time insights into financial performance, empowering Coca-Cola with the data needed for informed decision-making. This capability supported better financial planning, forecasting, and budgetary control.

Implementation of SAP ERP

Project Initiation

- Team Formation: Assembling a dedicated team for SAP implementation.

- Planning and Goal-Setting: Defining project objectives and establishing a roadmap.

Configuration and Customization

- Tailoring SAP ERP: Customizing the ERP system to align with Coca-Cola’s unique requirements.

- Integration with Existing Systems: Ensuring seamless integration with the company’s current systems.

Training and Change Management

- Employee Training Programs: Implementing training initiatives for staff to adapt to the new ERP system.

- Strategies for Organizational Change: Developing strategies to manage and navigate organizational changes associated with the SAP implementation.

Impact of Implementating SAP ERP

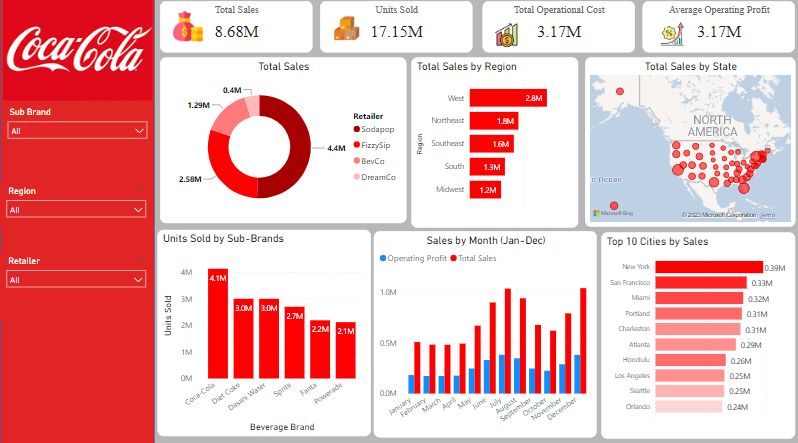

Coca-Cola implemented the SAP ERP system in 2003, incorporating it into a wide array of services across 45 countries with 15,000 users. The SAP ERP modules, including supply chain, Human Resources (HR), and Finance, are pivotal for Coca-Cola’s operations, spanning sales and marketing, accounting, production, supply chain management, HR, and customer relations. Efficient data sharing, especially with the finance department, is a crucial aspect of ERP for smooth transactions within Coca-Cola.

Supply Chain Management (SCM) plays a crucial role in optimizing revenues for an organization. For Coca-Cola, SCM starts with procuring materials and ends with the distribution of finished products. The company utilizes SAP and blockchain technology to optimize collaboration with partners, reducing the time for order reconciliation and providing real-time insights into transactions.

Coca-Cola’s Customer Relationship Management (CRM) employs advanced technology, including the Telescope software program. The CRM system engages Customer Service Representatives (CSRs) through modules like the Agent module and the Automated Call Distribution Module (ACDM), enhancing order management and customer service. The integration of SCM and CRM through an ERP system gives Coca-Cola a competitive advantage, enabling quick responses to supply chain issues and fostering strong customer relationships, ultimately leading to increased client loyalty.

Key Takeaways

Coca-Cola’s embrace of SAP ERP has led to transformative changes across its order management, production, and financial processes. The system’s automation streamlined order processing, reduced fulfillment times, and enhanced customer experiences. In production, real-time visibility and efficient demand forecasting optimized operations, minimizing bottlenecks. Financial processes saw improvements through the automation of transactions, providing real-time insights for better decision-making.

SAP ERP’s impact extends to Supply Chain Management, where blockchain technology enhances collaboration, and Customer Relationship Management, fostering strong client loyalty. This holistic integration has given Coca-Cola a competitive edge, creating an agile, efficient, and globally unified operational platform. The success of this implementation exemplifies the power of technological integration in propelling a renowned brand toward innovation and sustained success in a dynamic industry.

Seeking a powerful content marketing solution? Look no further! Visit our website to explore how our services can enhance your business with impactful WhatsApp marketing. Reach out to us now!

All images belong to their respective owners. Please email [email protected] if removal is required.