Choosing to invest in an ERP system is a big decision for a business. ERP brings benefits to different parts of the organization, like finance, HR, planning, and operations.

One important area where a well-set-up ERP system can really help is in supply chain management (SCM). As supply chains get more complicated, an ERP system can simplify things, work with other logistics systems, make sure products move smoothly, and ensure they’re always available.

Understanding Supply Chain Challenges

Modern supply chains face a myriad of complexities that can pose significant obstacles to seamless operations. These challenges include intricate networks, global sourcing, and dynamic market demands.

Common Bottlenecks and Inefficiencies

Within supply chains, common bottlenecks and inefficiencies arise in areas such as inventory management, transportation delays, and communication gaps between stakeholders. These bottlenecks can lead to increased costs, delays in product delivery, and customer dissatisfaction.

Need for a Comprehensive Solution

The intricate nature of supply chain challenges necessitates a comprehensive solution. Addressing isolated issues may not yield sustainable improvements. Instead, businesses require holistic approaches that consider the entire supply chain ecosystem, integrating technology, process optimization, and strategic planning to create efficient and resilient supply chain operations.

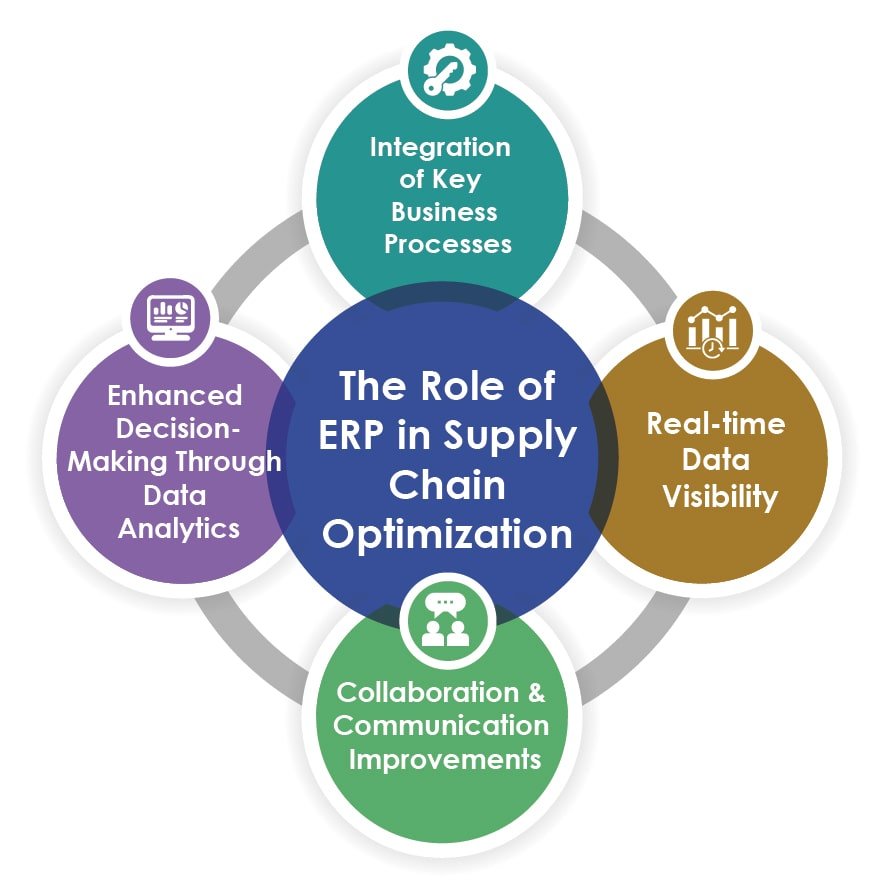

The Role of ERP in Supply Chain Optimization

ERP systems are integral to optimizing supply chains, seamlessly integrating business functions and providing real-time insights. They streamline inventory management, demand forecasting, and logistics coordination, boosting productivity and customer satisfaction in the supply chain realm.

Let’s understand this better:

Integration of Key Business Processes

ERP systems streamline supply chain operations by integrating essential business processes. This includes seamless coordination between procurement, production, distribution, and other elements of the supply chain. Integration reduces silos, enhances data accuracy, and promotes a more synchronized workflow.

Real-time Data Visibility

ERP solutions provide real-time visibility into various aspects of the supply chain. This visibility allows stakeholders to track inventory levels, monitor order statuses, and respond promptly to changes in demand or supply. Real-time data ensures that decision-makers have the most up-to-date information for effective planning and execution.

Collaboration and Communication Improvements

ERP fosters improved collaboration and communication among different departments and partners within the supply chain. By creating a centralized platform, ERP systems enable efficient sharing of information, reducing communication gaps and ensuring that all stakeholders are on the same page. This collaborative environment enhances responsiveness and agility in addressing challenges.

Enhanced Decision-Making Through Data Analytics

ERP systems leverage data analytics tools to provide valuable insights into supply chain performance. By analyzing historical data, current trends, and future predictions, decision-makers can make informed and strategic choices. This data-driven approach helps optimize inventory levels, forecast demand accurately, and identify areas for continuous improvement within the supply chain.

Advantages of Implementing ERP in Supply Chain Management

Implementing ERP in supply chain management offers a range of benefits, including increased efficiency, cost reduction, improved customer satisfaction, and enhanced adaptability to market changes. These advantages collectively contribute to building a more resilient and responsive supply chain, fostering long-term success for the business.

Increased Efficiency and Productivity

ERP systems streamline and automate various supply chain processes, leading to increased operational efficiency. By eliminating manual tasks, reducing errors, and optimizing workflows, businesses can enhance overall productivity, ensuring a smoother and more efficient supply chain operation.

Cost Reduction and Resource Optimization

Implementing ERP in supply chain management allows organizations to identify cost-saving opportunities and optimize resource allocation. Through better inventory management, reduced lead times, and improved demand forecasting, businesses can minimize excess costs, enhance cost-effectiveness, and allocate resources more judiciously.

Improved Customer Satisfaction

ERP systems contribute to improved customer satisfaction by ensuring timely and accurate order fulfillment. Real-time visibility into inventory levels and order statuses enables businesses to meet customer demands promptly. Additionally, enhanced communication and collaboration within the supply chain contribute to better customer service and satisfaction.

Enhanced Agility and Adaptability to Market Changes

ERP systems equip businesses with the agility to adapt to dynamic market changes swiftly. By providing real-time data and insights, organizations can respond promptly to shifts in demand, supply chain disruptions, or changes in market trends. This adaptability is important for staying in competition in this business world.

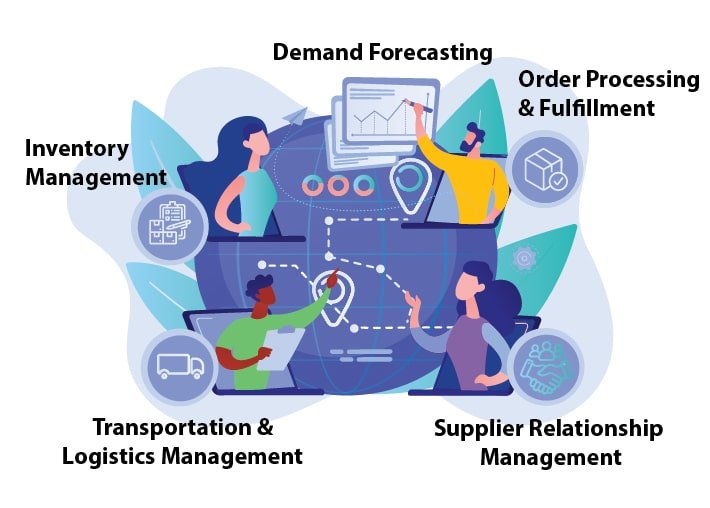

Key Features of ERP Solutions for Supply Chain

The key features of ERP solutions for supply chain management encompass inventory management, demand forecasting, order processing and fulfillment, supplier relationship management, and transportation and logistics management. Together, these features empower businesses to build a well-organized, responsive, and efficient supply chain ecosystem.

Inventory Management

ERP systems offer robust inventory management capabilities, providing real-time visibility into stock levels, locations, and movement. This feature helps businesses optimize inventory, reduce carrying costs, and ensure product availability when needed.

Demand Forecasting

ERP solutions incorporate advanced forecasting tools that analyze historical data, market trends, and other variables to predict future demand accurately. This feature aids in aligning production and procurement processes with anticipated market needs, minimizing excess inventory and stockouts.

Order Processing and Fulfillment

ERP streamlines order processing and fulfillment by automating order entry, tracking, and fulfillment processes. This ensures accuracy in order execution, reduces lead times, and enhances overall customer satisfaction through timely and error-free deliveries.

Supplier Relationship Management

ERP systems facilitate effective supplier relationship management by centralizing communication and collaboration with suppliers. This includes features for tracking supplier performance, managing contracts, and ensuring timely deliveries, contributing to a more efficient and reliable supply chain.

Transportation and Logistics Management

ERP solutions include features to manage transportation and logistics efficiently. This encompasses route optimization, shipment tracking, and real-time visibility into the movement of goods. This feature helps businesses reduce transportation costs, enhance delivery timelines, and optimize the overall logistics network.

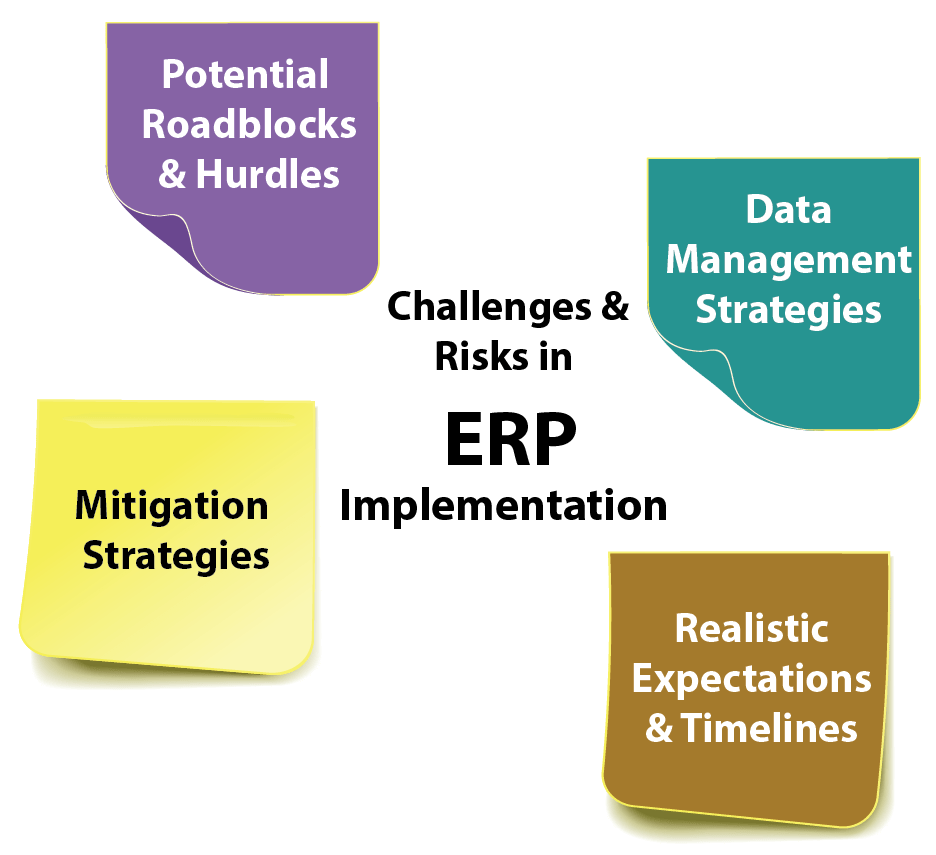

Challenges and Risks in ERP Implementation

Understanding and proactively addressing potential roadblocks, data migration challenges, customization issues, and setting realistic expectations with careful planning are crucial for successful ERP implementation. Mitigation strategies play a pivotal role in navigating these challenges and ensuring a smooth transition to an optimized and efficient ERP system.

Potential Roadblocks and Hurdles

- Resistance to Change: Employees may resist adopting new processes and technologies, leading to challenges in implementation.

- Data Migration Issues: Transferring data from existing systems to the ERP can be complex, resulting in data integrity issues.

- Customization Challenges: Customizing the ERP system to align with specific business needs may pose challenges and require careful consideration.

Mitigation Strategies

- Change Management: Implement robust change management strategies to address employee resistance, including training programs and communication plans.

- Data Quality Assurance: Conduct thorough data cleansing and validation before migration to ensure data accuracy and integrity.

- Careful Customization Planning: Clearly define customization needs and engage with ERP vendors to ensure a balance between customization and maintaining the system’s integrity.

Realistic Expectations and Timelines

- Underestimating Time and Resources: Organizations may underestimate the time and resources required for ERP implementation, leading to delays.

- Overambitious Goals: Setting unrealistic expectations regarding the system’s capabilities or the speed of implementation can result in disappointment.

Mitigation Strategies

- Comprehensive Planning: Develop a detailed project plan, considering all aspects of implementation, and allocate sufficient resources.

- Phased Implementation: Adopt a phased approach to implementation, focusing on core functionalities first before expanding to more complex features.

- Continuous Communication: Maintain transparent communication with stakeholders to manage expectations and address any concerns promptly.

Conclusion

Investing in an ERP system is a significant decision for businesses aiming to optimize supply chain operations. Beyond addressing challenges in finance, HR, and planning, ERP systems prove invaluable in simplifying complex supply chains, ensuring smooth product flow, and maintaining availability.

The benefits of ERP in supply chain management are evident, with increased efficiency, cost reduction, improved customer satisfaction, and adaptability to market changes. Key features, including robust inventory management, demand forecasting, streamlined order processing, effective supplier management, and efficient logistics, contribute to building a responsive supply chain.

Elevate your business experience with our diverse array of digital marketing services. Experience a surge in your sales and unlock new avenues for growth. Explore our website now for more details!